An Introduction to Industry 4.0 and Manufacturing Ecosystems

The 4th Industrial Revolution and Manufacturing Ecosystems are the integration of different manufacturing partners with information technology, data, and analytics.

Therefore,

Manufacturing ecosystems combine the components of equipment in the assembly line with sensors, smart materials, and real-time data. They provide a communication loop that acts in real-time, predicts changes, and plans for them.

In other words...

Above all,

You get flexible manufacturing services with extreme personalization.

In addition,

Here are the topics that we will cover in this complete guide to Manufacturing Ecosystems:

Now that we have answered the question, What Are Industry 4.0 Manufacturing Ecosystems? it is time to learn how they actually work.

When you use a manufacturing ecosystem to make your products, many parts integrate on the back-end.

For instance,

The Internet of Things (IoT) and everything it connects. Including autonomous robotics, mobile, cloud, big data analytics, 3D printing, sensor technology, virtual and augmented reality, to name a few.

How do Manufacturing Ecosystems speed up production?Even though there are many technologies at play, the main catalysts of the 4th Industrial Revolution are next-gen technologies such as AI, IoT, and Blockchain.

Let's discuss each one in more detail:

Artificial Intelligence (AI)

If you see a product that looks perfect but breaks down soon after its first use, you do not want to assume what went wrong because you cannot see the flaw.

That is to say,

As large amounts of data get generated, artificial intelligence can identify the areas that need more attention.

But, Artificial Intelligence does not only identify the products that need attention. That is because AI uses machine learning techniques to learn from each iteration what works and what does not.

Industry 4.0 at work!

For example,

To manufacture products, you first need to buy the necessary resources, and sometimes prices can get out of control.

But artificial intelligence understands that.

Therefore,

Your company increases profit, because machine learning algorithms analyze historical and competitive data.

Subsequently,

It generates price forecasts, and in return, you get more accurate price recommendations.

IoT (Internet of Things)

IoT technologies integrate the digital and physical worlds via sensors.

In other words,

These sensors get affixed to physical devices and networking technologies that collect data.

The question is...

In the new Industry 4.0, how does IoT turn digital technologies into physical objects?

A good example is when a product design gets created via software or the scanning of a physical object. This process creates data.

Most importantly,

The data is then communicated to the machines that execute the plan.

That is to say,

AI-powered robots can interpret CAD models. This eliminates the need to program their movements and processes. Which, in turn, brings the drawing from a digital to a physical state.

Physical-to-Digital-to-Physical

The actions previously described are known as a physical-to-digital-to-physical transition

That is to say, manufacturing systems and the objects they create are not only connected.

In other words...

In the new Industry 4.0, they are not merely drawings that send physical information into the digital realm.

But, they actually communicate, analyze, and use the information they collect. Then, drive further intelligence back to the physical world.

In fact...

IoT can send back and forth data cycles between the digital and physical realms. This is what separates it from the old manufacturing systems that came before it.

Making existing products... smarter!

Blockchain

New technologies can be promising and disruptive. The critical question is knowing when they are essential.

Blockchain is one of them.

Why?

Because it actually solves a significant problem. The complicated management of supply chain networks.

In fact, post Coronavirus, every industry will demand trust, transparency, speed, and agility.

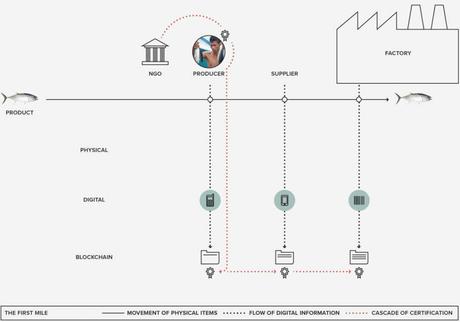

Blockchain technology is a catalyst for how the flow of goods goes from the producer to the consumer. This improves the transparency, speed, and responsiveness of these complex ecosystems.

A Blockchain Example

Let's say you go to your local grocery store and buy Tuna Fish.

However,

There is one thing you do not see.

It is the inefficient and complicated inter-connectivity of different networks on the back-end. Such as suppliers, manufacturers, distributors, retailers, and auditors.

Certainly, that is one complex supply-chain network the tuna fish had to traverse! And all that even before it reached your local grocery store.

Consequently, here is where Blockchain becomes interesting.

Say the local fishermen added blockchain technologies to their catch. You will now be able to see the origin of the tuna-fish.

Talking about Industry 4.0 transparency!

Building Trust & Transparency

Furthermore, you can follow its travel along the supply chain. From the actual catch to the moment you buy the tuna fish.

In short,

It is this kind of open system that creates traceability.

Most importantly,

It builds trust and transparency for food and other physical goods.

Above all,

It empowers consumers to actually see and know what they eat and buy!

This is more than ever true for consumer goods. Especially electronics, pharmaceuticals, and luxury brands. Which are susceptible to counterfeiting and fraud.

To sum up,

Blockchain has the potential to enhance the consumer experience. Through traceability, transparency, and tradability.

My #1 Tip for Growth In The 4th Industrial Revolution

Transact with Manufacturing Ecosystems designed with time-stamp, tracking, and automated transactions. These events can get audited in real-time!

Make sure they have established proof of quality, provenance, payment, and performance. This will help end counterfeiting and fraud.

From Shore to Plate: Tracking Tuna on the Blockchain

From Shore to Plate: Tracking Tuna on the Blockchain And now, it is time to delve into the main components of Industry 4.0 and Manufacturing Ecosystems.

In most cases, when people think of Manufacturing Ecosystems, they think of Extreme Personalization. This is why we are going to focus on flexible and faster product-to-market manufacturing in this guide.

The Coronavirus crisis was a significant eye-opener. It showed us most global manufacturers are not prepared for major market events. Nor are they ready for fast changes in demand.

Why?

Their operating models are old and obsolete.

This is particularly true of those that operate their own facilities. Such manufacturers are less productive, less profitable, and generate less revenue.

Manufacturing Post COVID-19

Post-crisis, there will be significant pressure on manufacturers. They will need to become as flexible as possible. In some cases, they will have to completely pivot at the drop of a hat.

This is where 4th Industrial Revolution Manufacturing Ecosystems shine.

Why?

Because they have optimized their manufacturing processes networks with contracted manufacturers.

These include:

- Product design

- Redesign services

- Product management

- Direct order shipment to customers

- Customer-requested customizations

- Bundling.

Manufacturing Ecosystems increase flexibility and speed-to-market by bringing third-party partners. The more different their capabilities, the higher their chance of success.

(For example, contracted workers could be a more significant chunk of the workforce of a company).

Why?

Because it enhances their flexibility, responsiveness, and performance with shorter product life cycles.

Third-and fourth-party logistics providers fall under two distinct business models.

Image by Warehouse Anywhere

Image by Warehouse Anywhere 3PL Logistics Providers

3PLs handle various aspects of the supply chain. They are more focused on day-to-day operations. Frequently, they own warehousing or transportation assets.

In other words, third-party logistics providers serve as intermediaries between manufacturers and retailers.

Some of the services rendered by 3PL include:

- Transportation

- Warehousing

- Cross-docking

- Inventory management

- Packaging

- Freight forwarding

Pro Tip: 3PLs are great for local and international distributions. They are also more affordable for small businesses with fast-growing orders.

4PL Logistics Provider

Fourth party logistics providers offer higher levels of supply chain management. They act as a single point of entry between all aspects of the supply chain and the client.

Most often, they do not own any assets. Instead, their goal is to coordinate all aspects of the supply chain with vendors. Their focus is to optimize the process flow.

Some of the services rendered by 4PL logistics companies include:

- Freight sourcing strategies

- Logistics strategy

- Consultancy

- Analysis of transportation expenses

- Analysis of carrier performance

- Effective management of third-party logistics

- Business planning

- Project management

- Proper management of inbound, outbound and reverse logistics

- Proper coordination of an extensive supplier base in various geographic locations

- Change of management

- Network analysis and designs

- Analysis of capacity utilization

- Proper inventory planning and management

Pro Tip: 4PLs work best for established enterprises. They are usually too costly for small businesses. 4PLs oversee the end-to-end supply chain mix of warehouses, transportation, and agents.

In summary, when we talk about 3PL and 4PL in Industry 4.0 Manufacturing Ecosystems, we refer to third-party providers. They offer location flexibility. They also provide added-services that position your company as a key player in your industry.

Postponement Centers allow companies to wait as long as possible to customize, personalize, and configure products and packaging.

In short: A company delays one or more of the final steps of producing a product until it has been purchased.

In fact...

By doing so, businesses offer customization to customers while reducing on-hand inventory. This lowers capital and increases free cash flow.

Postponement Center Example

Let us illustrate the importance of postponement centers with an example...

Let us say that you sell bicycles. Instead of storing finished bikes, you save in storage all the parts of the bicycles. Then assemble them only when an order comes in.

You can also create parts that can be used for many different types of bicycles, so you save inventory. If the demand moves from one to another, you can adjust fast.

When you delay or customize the final assembly of your product until the last minute, you have more flexibility.

Why?

Because you can create different products that use a wide assortment of similar parts. And assemble them only when the order has been received. Thus cutting out inventory waste.

Postponement Center Strategy

For example, most manufacturing takes place in China, India, and Central American countries. Thus, it may not be possible for the U.S. to compete with them when it comes to labor costs.

So, how can then the United States compete with these low-cost countries?

It can compete in the area of faster delivery times. Or product-service interaction, which must take place onshore.

In other words...

This is a 3-pronged strategy.

- First, manufacturers produce a generic product. It can be modified at the later stage, before the final transport to the customer.

- This involves build-to-order and mass customization strategies. It should be designed to mass-produce standard products to a forecast. Then ship them to their local markets.

- Products are then locally finished according to updated forecasts or specific customer demands.

Postponement Center Applicability

Postponement Centers currently cover a breadth of industries.

It is widely used in the automotive, apparel, and consumer electronics industries.

This is a profitable business strategy. Besides, it creates local jobs because of the inherent product-customer interaction.

As consumers demand more flexibility and faster delivery, businesses are feeling the pressure. Industries in the local production for local consumption categories are ripe for disruption.

Welcome to the 4th Industrial Revolution!

Pro Tip: Postponement Centers are the most efficient means of combining postponement and offshoring.

A manufacturer can benefit from third-party product and manufacturing design services. This is because they complement their own capabilities. It is especially true if the manufacturer does not have an in-house design team.

Some of the services offered by third-party innovation and design companies are:

- Product development

- Industrial design

- Mechanical engineering

- Electrical design services

Below is a list of third-party providers Manufacturing Ecosystems use in the 4th Industrial Revolution:

- Fast innovation cycles to help ideas get to market quicker

- Redesign of mature products that need renovations or revisions

- Technical documentation

- Prototyping and Testing

Before you dive into the nitty-gritty of outsourcing your product design, ideas, and innovations, it is essential not to skip the necessary steps.

One being, how to prepare your Innovation and Design work with an Industry 4.0 ready, third-party company.

Sound good?

Here is how to do it.

In The 4th Industrial Revolution, Think Your Idea Thorough

If you already run a business, most likely you already have a good idea. And you already know who your customer is and what your target customer wants.

(Also known as a Customer Persona).

But if you do not, this may cause a lot of conflicts in the manufacturing process.

In other words...

Understanding your customers and your product is essential. It lessens any chance for confusion when prototyping or creating your product idea.

You see...

Some of the best products or inventions in the market usually fulfill a market need.

So approaching a market idea this way does not only help you create saleable products. It is also a super important part of a successful design process.

I will explain...

To outsource your inventions and designs, you need to make sure who you will be marketing your product to. You also need to understand your market and your audience. Finally, you have to find out whether your product was previously created.

Unless you know who your customer is, and what your product does, it will be difficult for the design team to understand your idea. What is worse, they will not get a clear vision of what you want to create.

Write It Down

What is the best way to understand what your idea is? Write it down!

Have a document or notebook filled with notes about the details and ideas of your product. Save it in an organized way. This helps you have a clear image in your mind and understand what you want to create.

It also helps you communicate what you want to the design team.

Writing things down is the perfect way to receive clarity you need for certain aspects of the development of your product.

At the end of the process, you will have a detailed idea of your product. You can refer to it again and again.

Nice!

Ask Questions During The Industry 4.0 Idea Meeting

Let us be honest. Most business owners are not engineers or designers. Especially in the new 4th Industrial Revolution ecosystem!

Now that you have a clear product idea, it is time for the next step: the idea meeting. It is essential to think about what you would like to know more about your product.

Here is where you will ask the design team for clarity. Especially in certain aspects of the development of your product.

This is where having questions about the product development process itself is crucial.

You want to know how the team will approach the development of your product design. This will avoid any confusion and save you lots of headaches down the road.

Keep In Touch

Let us say that you had your first idea meeting.

By now, you...

- Understand your customer

- Have a clear idea of your product

- Know how it fulfills a market need

- Understand the design process of the team

- Selected Industry 4.0 ready vendors

But...

You need more time to think about the details of your project. Or you may need to re-invent and re-design certain aspects of your design.

So, to succeed in outsourcing your design ideas, you want to make sure you keep in touch with the design team.

That way, if you need help or advice, you will know the design team is responsive.

And, to be honest, it can take a lot of time to have a clear idea of the details of your product or invention.

Finally, if they are not responsive, do not call you back, or do not follow up with you. Then that is a red flag you must take into consideration before moving forward.

In other words:

It may not be the right fit for you.

Why?

Because if they do not get back to you so early in the relationship, imagine later on when you already paid them money.

It is no secret that critical skills have become harder to find.

In general, the more skilled your workforce, the higher the performance of your company will be.

But it is (obviously) not that simple. So it is a good rule of thumb to fill the void with high skilled third-party labor pools.

This is how manufacturing ecosystems can fill that void. They offer services from advisory to full operational control in manufacturing functions. Such as engineering, safety, and maintenance.

But...

This outsourced workforce should still be high-quality. They most definitively should be 4th Industrial Revolution ready and trained!

The fact that you are going through an intermediary does not mean you are willing to accept lower quality labor.

In fact, the main goal of using third party providers is so you can get high-quality employees. Even if they are not hired by you.

As your workforce ages and retires, you can replace them with Industry 4.0 trained freelancers or contracted workers.

Industrial MRO refers to the maintenance, repair, and operations of machinery and equipment. These are mainly used in an integrated supply chain management model.

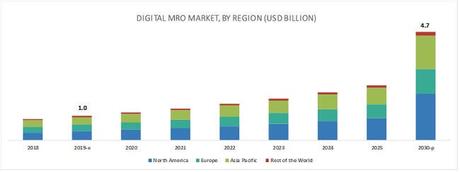

The digital MRO market is projected to grow from USD 1.0 billion in 2019 to USD 4.7 billion by 2030

Digital MRO Market By Region What is driving this growth?

Digital MRO Market By Region What is driving this growth? Massive demand in predictive maintenance. This is, in part, failure analysis and part troubleshooting.

In other words...

Predictive maintenance allows 4th Industrial Revolution manufacturers to address problems before they cause equipment failures.

This, in turn, helps them reduce costs. Also, extend equipment life, minimize downtime, and improve production quality.

As we speak, here is how the industry is evolving...

4th Industrial Revolution Technology Drivers

Large MROs are investing in new technologies. Such as AI, blockchain, and digital twins to reduce maintenance cost and downtime.

Based on technology, the Industry 4.0 digital MRO market segments are as follows:

- Predictive Maintenance

- AR/VR

- 3D Printing

- Blockchain

- Artificial Intelligence

- Robotics

- Big Data Analytics

- Digital Twin

- Internet of Things (IoT)

But how can these MROs help you and your business?

MRO Applicability

In an Industry 4.0 smart manufacturing ecosystem, manufacturers use MRO hubs for standard parts, assets within an industry, a manufacturing process type, or an applicability segment.

Such as...

- Inspection

- Performance Monitoring

- Predictive Analysis

- Part Replacement

- Mobility & Functionality

These are valuable because most businesses ignore MRO parts. What is worse, they manage them in a distributed manner using lots of different sources.

So, for example, these businesses, instead of having a hub for standard parts, have these parts all over. This causes a rise in costs, and their performance gets dampened.

Thanks to these MRO Hubs, you now have a one-stop-shop for all your maintenance needs.

And because now you have equal or better parts availability, you need less investment in inventory.

This reduces warehouse space, carrying costs, and labor to plan and stock.

Now you see the benefit of MROs, right!?

Pretty cool.

Pro Tip: To offset tariff impacts, use local, Industry 4.0 ready, sourcing for non-critical/non-OEM spare parts.

*OEM (Original Equipment Manufacturer)In other words...

You will be able to buy digital representations of products. Whether standard and proprietary, ...and manufacture them yourself.

How?

3D-Printing Marketplaces

By having the designs ready to get produced, you can save time. So these marketplaces can lower your manufacturing costs.

Especially in regards to time saved in innovation and design.

That is why it is vital to keep an eye on these digital marketplaces. This way, someone else does not beat you to a product design that fits your target market .

(More on this in future posts)

For now, make sure you start to research and build relationships with Industry 4.0 ready Manufacturing Ecosystems.

Be ready!

Proof of Concept

If you already have a business, I recommend you start creating PoCs (Proof of Concept) projects.

No, a PoC is not a magic bullet that will make you into an overnight success.

But PoCs will make it easier for you to get started understanding Industry 4.0 and Manufacturing Ecosystems. You can be ready when you design or find a killer product for your business.

It also helps you establish a solid relationship with potential manufacturers.

Think about it this way:

While your competition is trying to figure out how these 4th Industrial Revolution manufacturing ecosystems work. Or what is worse, they are finding out about it. You will be light years ahead and ready to hit the ground running.

Direct-to-Consumer Online Stores

Part of our strategy is to help companies stack their growth.

Why?

So, business owners do not become overwhelmed. The transition from offline to direct-to-consumer online sales can be tricky. Then things get more complicated when they scale to wholesaling.

iGrowStack eCholita D2C Monthly Drop

iGrowStack eCholita D2C Monthly Drop Furthermore...

What do I mean?

Well, only data can tell you which direction your business should take.

But if this is the first time you will be selling directly to consumers. Then you really do not have a lot of data to make reliable, long-term decisions.

Does that make sense?

Optimize Your Direct to Consumer Store First

Your initial Proof of Concept online store design is not nearly as necessary as the data it generates.

Why?

Why should you even bother with first-party data? Because the real value of your business is not just your infrastructure or the products it produces.

The real value of your business is the 1st-party data it generates.

Benefits of Increasing Exit Value

For example...

In 2016, Unilever paid $1B to buy the 5-year old Dollar Shave Club. This acquisition marks one of the biggest e-commerce deals in recent years.

Why would Unilever pay such an astronomical price?

Because Unilever would benefit from the Dollar Shave Club. Specifically, their valuable customer data and existing customer base.

Yup, they paid that amount because of the unique consumer and data insights of the Dollar Shave Club.

After all, Dollar Shave Club is the category leader in its direct-to-consumer space.

Pro Tip: Do not just rely on Amazon for your online sales. By doing that, you are increasing the value of Amazon instead. Not yours. Now, do not entirely drop Amazon either, but use it only as a complementary sales channel.

I hope you enjoyed this Industry 4.0 guide for beginners. I wanted to go beyond just answering what a 4th Industrial Revolution Manufacturing Ecosystem is? And actually give you a few concrete steps to get started.

As you can see, there is a lot to learn about the new technologies affecting this massive paradigm shift.

Considering how much these Manufacturing Ecosystems can help your business transition into the new economy, it is worth the time and effort.

So I recommend getting started with the basics:

- Make sure you learn from the changes of the past decade. Think of cloud, analytics, and digital experience as the new normal.

- Consider what they mean for future trends and embrace technology at the core.

- Finally, keep your eye on the horizon . Trends like Blockchain, artificial intelligence, and IoT are the next significant changes in how we will do business.

These three steps are the foundation of Industry 4.0 and Manufacturing Ecosystems.

And once you feel like you have understood their relation to the 4th Industrial Revolution, start looking into the more advanced stuff, like SEZs (Special Economic Zones) and Additive Manufacturing.

[thrive_leads id='4998′]

Now It's Your Turn

So that's it for my guide to Manufacturing Ecosystems

Now I'd like to hear what you have to say:

- Which strategy from this guide are you going to try first?

- Do you plan on launching your own product?

- Or maybe you want to test out your own PoC (Proof of Concept) project?

Either way, let me know by leaving a quick comment below.

You Might Also Enjoy...

More Resources...