Distributed Local Manufacturing Near Me

Some people ask: Can moving my manufacturing near me, help me mitigate business risk?

The truth is...

Some companies are better prepared than others to mitigate risk.

But, COVID-19 showed us how fragile businesses are. As well as the profound consequences when they are not prepared.

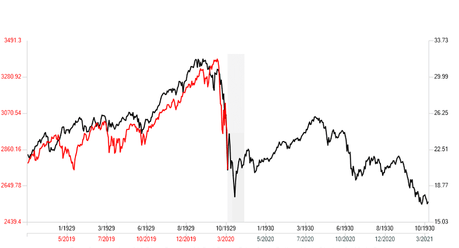

Data Source: Bloomberg 03/10/2020 08:21

Data Source: Bloomberg 03/10/2020 08:21SPX vs. 1929

1 Year Analog, Correlation = 91%, SPX 3/10/2020 = 10/29/1929 SPX

The Impact of Even Small Disruptions:

You see...

Most of the time, overwhelmed business owners do not have the time to see potential pitfalls.

Post Coronavirus, that is going to change.

Why?

Because the pandemic showed us how a small disruption in one link of the chain can have a significant impact down the line.

COVID-19 will be a catalyst for change.

Moving forward, companies will have to revisit their growth strategy and risk exposure.

In the short term, the consumer sector will be the one that hurts the most.

The first half of 2020 will be hard for catering, retail, and travel services. They will experience cash-flow pressure due to declining sales and high fixed costs.

The impact of these disruptions will increase as the time to recovery lengthens.

To make matters worse...

The shortfall in cyclical consumption will not recover after the pandemic.

Impact on SMEs.

Small and medium-sized service companies were particularly struck hard. Post COVID-19, these businesses can no longer rely on one sales channel only.

In other words...

Business version 2.0 is on the horizon.

What you are seeing today is a potential glimpse of the future.

What do I mean?

Service companies who had a physical location must add an online extension . They should use this experience as a lesson. Especially those that lost money because they had to close shop.

An online channel is now a must.

These organizations will need to speed up their adoption of a digital presence.

This will allow them to build their brand offline and online. Now is the time to get prepared!

This will also help them avoid total closure when (not if) another disruption - like COVID-19 - happens.

In other words...

Next time there is a crisis, one channel can continue while the other is rebuilding.

One thing is clear.

online sales, eCommerce, and will inherit the future.

Manufacturing Near Me

So if you have ever asked yourself: Where can I find ?

You may want to Google things like: Where are the manufacturing companies near me? Even...are there any manufacturing plants near me? How about...are there industrial companies near me?

Once you find the right local manufacturer, this is where Distributed Local Manufacturing will play a significant role. Especially post Coronavirus pandemic.

Finding the right vendor

This is where finding a distributed local manufacturing company will play a significant role. Especially post Coronavirus pandemic.

How?

The idea behind Distributed Local Manufacturing is to replace as much as possible the material supply chain. Then replace it with digital information.

This means...

The consumer can produce, manufacture, or assemble some of the parts of the products sold online.

Or...

They can get assembled by local fabrication workshops . These will then turn them into finished products.

An example of choosing manufacturing near me (you)

For example...

Let's say you sell chairs in your offline store.

Now, you will no longer source these chairs from third party vendors. Instead, you will get them manufactured yourself.

So, as a first step...

Instead of sourcing wood and fabricating them in a central factory, you keep them in a digital format.

Then, you distribute these digital plans to local manufacturing hubs. They then cut the parts of the chair using computerized cutting tools - known as CNC routers.

And turn them into custom built chairs.

Sounds simple, right?

Well, it never is.

These are gross oversimplifications of many strategic options you can take.

Complexities of local distributed manufacturing:

Let's be honest...

Assembling and packaging end products near their final destination are not simple. This process brings many complexities.

But...

It gets better...

These small-scale, local fabrication workshops will help you save on freight costs. They will also help you reduce lead-time and increase responsiveness.

Even though coordinating manufacturing across many different factories will always present challenges.

Using local fabrication workshops will give you more flexibility. They can help you source the best materials.

You will also be able to manufacture your products where you want.

And...

Do not forget, this strategy will help you reduce freight costs.

What should I expect when I look for Manufacturing Near Me?

Ok, so before you ask yourself, where are themanufacturing companies near me? This guide will help you clarify what to expect if you decide to go this route.

Here are the topics we will cover in this Distributed Local Manufacturing guide:You may be wondering...

Why is Distributed Local Manufacturing Important for Mitigating Unpredictability?

Let's be honest. Business disruption is a reality of life.

For example...

The Coronavirus disruption may be soon coming to an end, but the next one is waiting around the corner.

What is worse... there will be natural disasters and other emergencies. And yes, more viruses too.

Not to mention, the post-pandemic global economic and financial ramifications. Which will impact all global supply chains. All the way from raw materials to finished products.

The Importance of Proper Preparedness:

This means that proper preparedness now is paramount for future business survival. It will save time and money down the line.

So building a backup plan is essential.

Not doing anything, most likely, will lead to another disaster.

Why?

Supply chain unpredictability is a reality of life.

There will always be " something" that comes up. Whether it is a pandemic, natural disaster, economic slowdown, or something else.

But you may say... " hey, I already planned for future events."

You may be right. But there is a vast difference between planned disruption and unpredictability.

Unpredictable issues can strike at any moment.

Issues such as natural disasters, outbreaks, political instability, trade war, or logistical problems.

Risks of Not Being Prepared:

According to FEMA, 40-60% of small businesses do not reopen after a disaster.

Even worse...

90% fail within a year if these small businesses are not able to resume operations within 5 days after a disaster.

This means...

If you want to save your local economy, hiring local fabrication workshops is a must. Not only for your own survival, but it is also good business practice.

In other words...

For every dollar of value, we create using local manufacturing. An extra $1.37 value gets created in other domestic sectors.

As billionaire . "... the idea of assembly-line manufacturing is the way to guarantee employment in trade. The first thing we need to do post COVID-19 is to start investing in the future of manufacturing ..."

The question is then...

What kind of services can I find if I move my manufacturing near me?

What can these local fabrication workshops offer me?

Common services include:

- CNC Machining

- 3D Printing

- Injection Molding

- Urethane Casting

- Sheet Metal

- Design

- Engineering

In other words...

These distributed local manufacturers make the process more accessible, customizable, and affordable.

The truth is...These local workshops are reinventing the manufacturing industry. From something monolithic and closed to something transparent and agile.

You may also be wondering...

Why would you want to use Distributed Local Manufacturing to reduce risk?Studies show, only a small percentage of companies feel prepared to confront risks. This percentage increases when it comes to supply chains.

Business owners are having a hard time dealing with manufacturing disruptions.

Companies are scrambling. The challenges are real.

Many of them rely on single geographies or a single supplier for critical products.

To make matters worse, some do not understand the complexity of supply chain networks. This makes it hard to see potential risks.

Others do not have the systems to understand their inventory status. Nor to project stock-outs of direct materials. This makes it hard to optimize production.

What is worse...

They do not have flexible logistics networks to ensure the flow of goods profitably.

Distributed local manufacturing to the rescue!

These can help entrepreneurs be more flexible. They can now choose from a variety of machines, materials, and quantities.

All located nearby, with unparalleled flexibility, quality, and speed.

As we have seen, a small disruption can have a considerable effect. Remember, life after COVID-19, will not be the same.

A crisis is not a time to learn, it is a time to act.

So keep in mind the questions below as you prepare your business for the future.

A quick check of your current capabilities include:

- What products can you move to your ?

- Can you create more products that can get sold online? (i.e., If you are a restaurant, can you create a "Secret Sauce" and sell it online?)

- Are you tech-savvy, or do you need ?

- Do you rely too much on a handful of vendors? In other words, if they fall, everything falls?

- Simplify! Simpler supply chains have less to go wrong.

- Do you have data ready so you can hit the ground running?

- Do you understand ?

Here are a few risk assessment questions you should consider:

- Do you have a Plan B and a Plan C?

- Have you diversified your supply chains from a geographic perspective?

- Did you multi-source vital commodities?

- Have you lowered your reliance on any one supplier?

- What are the failure points in your business?

- How do you deal with those in case of a disruption?

- What can you track, and how can you assess potential risk?

- How would those risks impact your company?

- How fast can you react and respond?

Most business owners, when they think about manufacturing, they think of high-volume manufacturers.

But...

These high-volume manufacturers do not always offer the best quality product. This is due to economies of scale and communication barriers.

True. These high-volume companies invest vast amounts of capital in warehouses. Which are full of machines that can fulfill demand.

Also true. These big players have an advantage when it comes to capital and resources.

Where they fall short is when it comes to speed and quality.

Benefits of Local Workshops:

This is where local workshops shine.

Larger manufacturers cannot compete when it comes to quality.

Why?

The big guys play the volume game, and quality often gets lost in the mix.

On the other hand...

Small manufacturers love their craft. This makes a huge difference when it comes to quality.

Manufacturing Near Me Directory

Manufacturing Near Me Directory Low-volume small local shops often have decades of experience. Most of them produce consistent, high-quality work.

Now, low-volume manufacturers use different processes, tools, and materials. So depending on what they use, their production ranges between 50 to 100,000 parts.

And their manufacturing can get leveraged by companies of any size. From start-ups to mid-size companies. Even large companies can take advantage of this strategy.

Low-volume manufacturers also offer agility. Especially within their production and distribution networks. This helps them fill demand fast.

This means...

Distributed Local Manufacturers are positioned for speed.

This is because smaller shops have fewer organizational layers.

High-Bureaucracy Challenges:

Compared to their larger counterparts, small local manufacturers can respond faster. This is because large manufacturers need to navigate through complex systems.

To complicate things even further...

Large manufacturers need to ship from the machine warehouse directly to the customer. These increase lead times.

Furthermore, remote manufacturers have to manage errors.

In summary: For high-volume manufacturers, there is a lot of complexity to deal with. These include large organizational layers, communication issues, and lost time.

Low-Bureaucracy Benefits:

But...

When you work with smaller, local manufacturers, parts can get picked up as soon as they are ready.

They can even get delivered via same-day courier. This can save up to 1-2 days of shipping.

In other words...

Low-volume local manufacturing ensures a faster time to market.

Success vs. Failure:

Let's be honest...

In a highly saturated, competitive market, a unique product can be the difference between success and failure.

So if you combine uniqueness with distributed local manufacturing and shorter lead times ...

...you created a massive market advantage.

Think about it...

Compared to traditional manufacturing methods. This allows products to hit shelves days, weeks, or months faster.

This is key for smaller businesses in the prototyping and ideation stages. Since at this stage, time is everything.

Even a 1-2 day loss from a 3PL (third-party logistics player) matters.

That said...

The challenge is in figuring out how to help these small shops optimize their operations.

Your goal is to make sure they are not overbooked while hustling to manage and grow a business of their own.

Consumer demand for local, personalized products is a trend that has been growing.

This new consumer paradigm shift presents massive opportunities. Both large and small corporations can benefit.

In other words...

To succeed in a local economy, unlocking these opportunities is essential. And the secret lies in using distributed local manufacturing operations.

One with a connected network of smaller, more agile, and flexible factories around the world. Better if located closer to where customers are.

And here is the secret...

Corporations must think globally. Especially when it comes to emerging customer needs. But, build locally when executing those needs.

You see...

Smaller, distributed factories with networks and ecosystems worldwide are more cost-efficient. Especially those that serve regional markets. As opposed to large production centers that ship products.

Here is why...

The factory of the past was a giant, rigid, single machine riveted to the floor.

How Manufacturing Is Changing:

Factories are becoming more flexible and versatile digital systems.

These new business models will be able to create various versions of products fast. Or reconfigure them if needed.

All with the least amount of downtime and a considerable reduction in supply-chain complexity.

Technologies Driving Change:

Today, robots are doing tasks previously performed by humans only.

This means...

New technologies enable close monitoring. They also coordinate and provide predictive maintenance of the different machines involved.

This reduces reliance on distant suppliers and manufacturers.

Small Quantity, Custom Built Manufacturing

Some smaller companies are already benefiting from these new technologies.

For example...

Some flexible local factories offer " à la carte" manufacturing. This allows them to produce small runs to serve more clients.

In other words...

These low-volume distributed local manufacturers provide design flexibility. This is something, mass manufacturing cannot match.

Many times, a design needs to get modified. When this happens, products need to get manufactured in smaller quantities. This will have a lesser impact on the bottom line.

This kind of flexibility will give you lots of peace of mind.

It will also give you time to improve, refine, or change your product even before it is ready to hit the market.

Furthermore...

Testing of a product can get done using realistic buying decisions. You can even have many product versions available for sale.

Continuous Improvement:

This allows you to analyze which features are more popular. Then improve your product for the next batch of production to meet customer demand.

So by using low-volume, distributed local manufacturing...

...you have the potential to save considerable sums of money.

Mainly because you will not get left stuck with vast amounts of unmovable inventory. Thus adding revenue and reducing risk.

But...

It is best if you deal with small local manufacturers. Primarily if they specialize in market niches.

Working with those that offer many services to different markets is difficult. And it is not a successful growth strategy.

Here is an example:

A 3D printing shop that focuses on FDM, for example, will be excellent in that area. But usually, they are not as skilled in SLA or Polyjet.

Focus on finding distributed local manufacturers that concentrate on what they do best. Which, most of the time, is what they love most.

Pro Tip: Find distributed local manufacturers that specialize. Avoid shops that are a jack of all trades.

You must be able to react fast to change and reduce disruptions. Primarily if you are operating a business in such uncertain times.

For this, you need closer proximity to your market.

So, a challenge you will face is the ability to change your production flows. This is key to meet the constantly changing consumer demand.

As mentioned earlier, technological advances are fast becoming available. This means that distributed local manufacturing is a better solution for many companies.

By using distributed local manufacturers, you can adapt to volatility much easier. You can also streamline your production.

Lower operating costs allow low-volume local manufacturers to adapt to any company size.

For example...

Your company can localize the actual product to best suit your particular market. You can then focus your marketing efforts on your local market.

So...

Let's say you have an idea to manufacture a new product. Under normal circumstances, you will need significant investment capital. Especially at scale.

This is true, even if you have the technical skills.

But...

If you use a local manufacturer, you can increase your responsiveness and agility to get it done.

Furthermore...

Geopolitical policies can make things messy.

The good news is that...

Goods produced closer to the consumer, are not subject to the same threat of changing tariffs.

As you accumulate data about your Perfect Customer.

And technologies like AI, machine learning, and advanced analytics become commonplace in manufacturing.

You will be able to predict demand and immediately make changes to match that demand.

You see...

Data-driven manufacturing can better estimate its output. Both price, and volume, can be set up-front for better performance and higher profits.

Understanding output also puts you in a better place. You will be able to negotiate better bulk deals with suppliers upfront.

In other words...

You can get rid of another unknown as your company picks up pace over the years.

How?

Business value gets based on the future expected performance (Cash Flow) of a business. Then a percentage of value gets discounted for any corresponding " Risk" (Fear).

This means that by eliminating the unknown, you are reducing " Fear."

In other words...

You have increased business value.

So to answer the original question: Can moving manufacturing near me help mitigate business risk? The answer is yes!

Learn More

[thrive_leads id='4998′]

Now It's Your Turn

So that's it for my guide to DistributedLocal Manufacturing Near Me (well, you in this case 🙂

Now I'd like to hear what you have to say:

- Which strategy from this guide are you going to try first?

- Do you plan on using a local manufacturing workshop?

- Or maybe you are already using one? (do tell!)

Either way, let me know by leaving a quick comment below (bottom of page).

You Might Also Enjoy...

More Resources...